The OBO clamp clip portfolio

More hold. More stability. More safety.

May we introduce The OBO clamp clips. The portfolio has been completely revised and optimised yet further. The result is certainly impressive. The clamp clips are now even more application- and installation-friendly and their hold has been increased considerably.

OBO possesses many years of expertise in the field of clamp clips and has developed and implemented the optimisation of the portfolio together with its customers. This ensures that the OBO clamp clips exactly fulfil the requirements of users in practice. Numerous installation challenges can thus be tackled: Using the OBO clamp clips, cables and pipes can be fastened efficiently and reliably to profile rails and cable ladders, but secure mounting on angular and flat irons and on round profiles is also child's play.

Every advantage of the OBO clamp clips at a glance

- Simpler handling during installation

- More rapid mounting with less effort and lower costs

- Better hold and more stability. This means: More safety.

- High material quality, function safety and material resistance

- Wide range of material types and surfaces

- Large selection of base shapes for a wide range of applications

- Maintenance of electrical function classes E30 to E90

- Special solutions can be implemented with ease

- Metal and plastic pressure trough

Thought-out down to the last detail

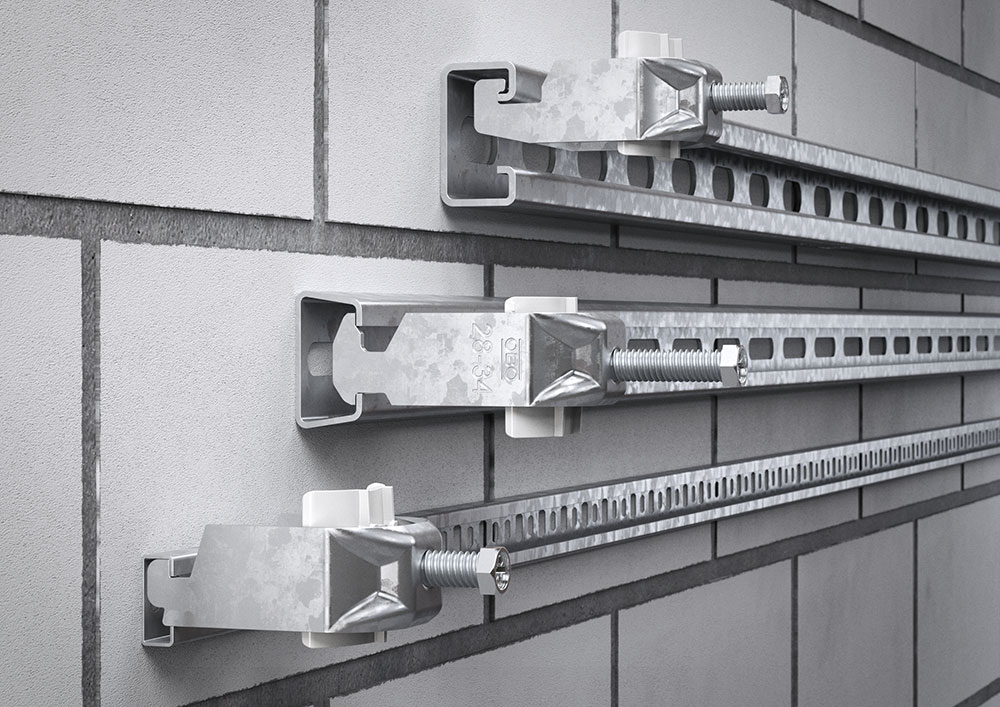

The OBO clamp clips stand out with robust surfaces and high-quality materials: They are available in versions made of aluminium (ALMG3), stainless steel A2, stainless steel A4 and steel with a hot-dip galvanised surface. However, they not only stand out through the range of materials, but also through further optimisations, such as a tightening torque of 2 Nm for aluminium, 3–5 Nm for steel and stainless steel A2/A4 and an increased clamping range of 8–100 mm.

Optimised portfolio for even simpler installation

The clamp clip portfolio was not only optimised with regard to the range of materials, but also in further points, making the installation of clamp clips even simpler than ever before. These include:

Screws:

- Same head (WAF10) for all screws (M6/M8)

- Fully standardised thread

- FT screw with 8.8 quality

Pressure trough:

- Increased material thickness for improved hold

- Versions available in PP or metal

- Metal pressure trough with rounded edges provides more cable protection

Clip element:

- Reinforcement in top area offers simpler mounting

- More stable screw connection through deep-draw method: The forces act on the entire clip body

- Large selection with six different standard base shapes

- Handle recess improves the feel during mounting

The right clamp clip for every installation situation

With a wide range of sizes and variants, the OBO portfolio can offer the right clamp clip for any installation situation. In total, six different main base shapes are available, which are all suitable for mounting in indoor and outdoor areas:

- N base: For vertical and horizontal mounting

on a C profile rail, slot width 11–12 mm

- H base: For vertical and horizontal mounting

on a C profile rail, slot width 16–17 mm

- U base: For vertical and horizontal mounting

on a C profile rail, slot width 18–22 mm

- W base: For vertical and horizontal mounting

on an angular iron of up to < 40 mm

- F base: For vertical and horizontal mounting

flat irons with 4–12 mm material thickness

- RS base: For vertical and horizontal mounting on round profiles with a diameter of up to 22 mm